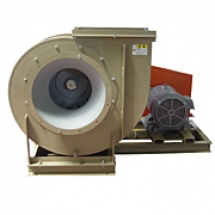

Showa Denki Large sized series (Denchoku) K1D4

Mã sản phẩm: K1D4

Tên thiết bị: Máy thổi khí

Xuất xứ: Japan

Tình trạng: Mới

Liên hệ: 0912 924 479

Giá:

Liên Hệ

| Air foil fan | Sirocco fan | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Turbo fan | Turbo blower | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

| The number in ( ) indicates overrated max. airflow. |

![]()

|

|

|||||||||||||||

SẢN PHẨM CÙNG LOẠI

-

Showa Denki Multi-stage series U type

Giá: Liên Hệ -

Showa Denki CFM type

Giá: Liên Hệ -

Showa Denki Turbo Fan & Blower T1V08

Giá: Liên Hệ -

Showa Denki Agitating/circulating series WE-04

Giá: Liên Hệ -

Showa Denki All-purpose series E type

Giá: Liên Hệ